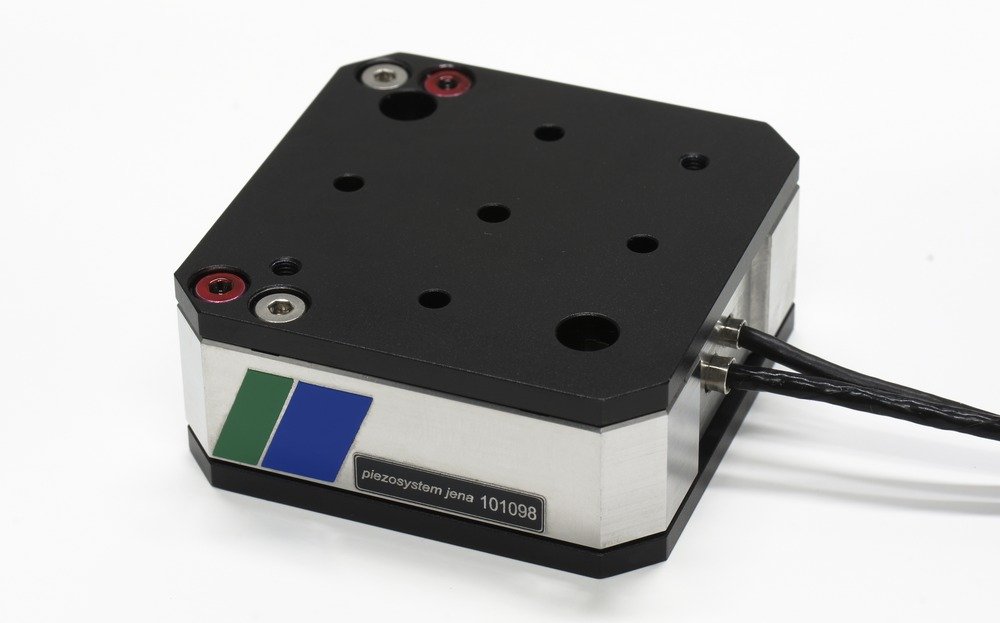

nanoX 400 – Description

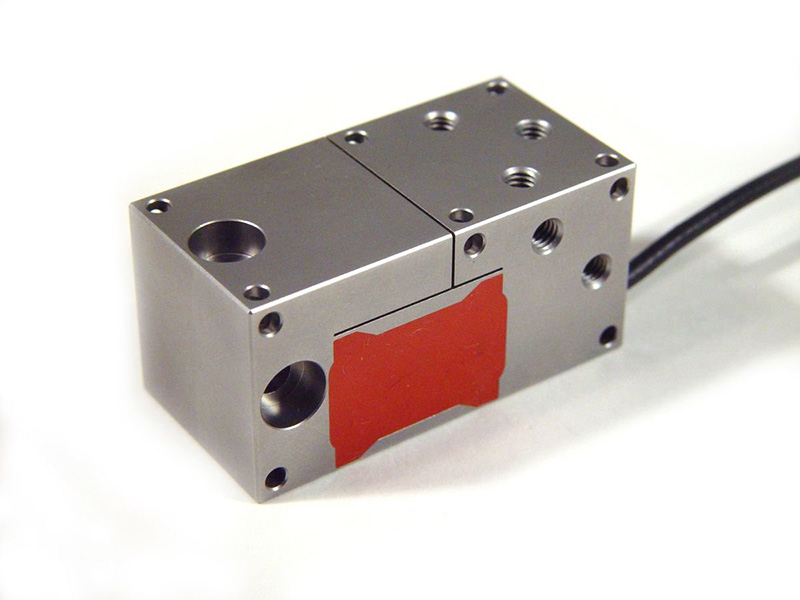

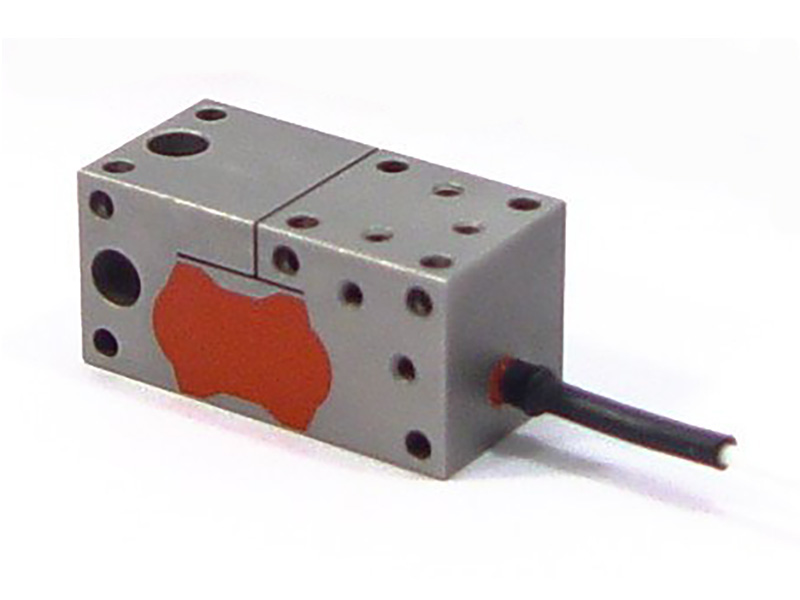

The piezo based nanoX® 400 is our ultra fast and high load positioning stage. It provides a positioning and scanning range of up to 480 micrometers. The centrally located free aperture allows laser optical applications through the stage. This is also possible when stacking them in an X, Y configuration. Due to FEA-optimization, the nanoX® 400 provides the highest dynamical performance and excellent guiding accuracy. This is accomplished even with high mass loads in a very compact package. The nanoX series is made for nano-positioning tasks in the field of semiconductor, laser & optics and test & measurement.

Our piezo stage optimization also incorporates excellent temperature compensation properties for the trajectory of the nanopositioning stage. The sophisticated monolithic guidance design of the solid flexure hinges means the trajectory is free of mechanical play and friction – a feature of all piezo stages and nano-positioners.

Based on solid-state phenomena, piezo actuators and piezo ceramics generate pressure forces to affect the leverage geared motion. The PZT ceramic’s extension is nearly linear to the applied electric field, but hysteresis and creep still exist. Piezo electrical geared stages and positioners are neither affected by nor produce magnetic fields. In cryogenic environments piezo actuators function down to almost zero Kelvin. This low temperature is associated with linear decreasing extension behavior. In vacuum conditions, piezo actuators and PZT ceramics can be used at pressures below 10 Pa.

Because of the greatly reduced dielectric breakdown strength of air, they should not be operated in pressures ranging from 10 Pa up to 10 kPa. To avoid creep and hysteresis, the piezo nano-positioner nanoX® 400SG or nanoX® 400CAP are equipped with a high resolution measurement sensor.

In combination with the piezo controller, high stability, linearity, repeatability and accuracy are achieved during closed-loop operation.

The compact piezo stage design and the raster pin and drill holes for mounting allow an easy integration of the nano-positioning stages nanoX into your existing assembly. Vacuum and cryogenic versions are available on demand, as well as body material variations of invar, superinvar, aluminum and titanium.

Technical Data

| UNIT | nanoX 400 | nanoX 400 SG | nanoX 400 CAP | |

|---|---|---|---|---|

| Part # | T-108-20 | T-108-21 | T-108-26 | |

| Axis | X | X | X | |

| Motion in Open-Loop (±10%)* | μm | 480 | 480 | 480 |

| Motion in Closed-Loop (±0,2%)* | μm | – | 400 | 400 |

| Resolution Open-Loop** | nm | 0.8 | 0.8 | 0.8 |

| Resolution Closed-Loop** | nm | – | 8 | 2 |

| Dimensions (L x W x H) | mm | 52 x 32 x 52 | 52 x 32 x 52 | 52 x 32 x 70 |

| Weight | g | 250 | 270 | 370 |